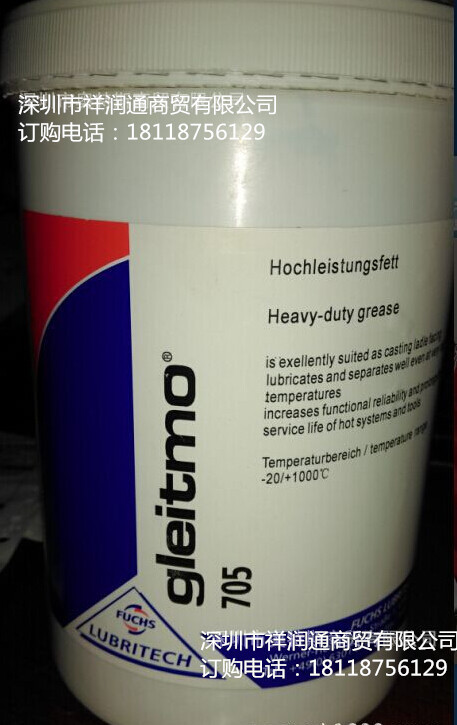

FUCHS ,福斯GLEITMO 705压铸机低速轴承,螺栓,铰链,拖鞋垫和滑轨上发射,干燥,退火系统的润滑. FUCHS GLEITMO 705

gleitmo 705是一个灰色的润滑膏,具有良好的扩展性,在高温下使用。 一个特殊的合成机油含有大量的gleitmo固体润滑剂组合提供该产品具有良好的润滑和分离性能。 载体油蒸发逐渐在连续的温度超过180°C。 干式润滑膜形成润滑混合和边界摩擦条件下+1,000°C,并提供抗磨损保护。 有只有很轻微的残余物从载体油,此残余物在随后的润滑过程中具有良好的效果。

应用领域 :

面对铸造铁水包,工具,渠道和嘴中铝压铸gleitmo 705是合适的。

低速轴承,螺栓,铰链,拖鞋垫和滑轨上发射,干燥,退火系统的润滑。 在模铸造厂铸造渠道。

压铸机:顶针和其他运动部件。

无论高温下无法使用的润滑油和润滑脂的动作缓慢的地方发生,或者是需要一个良好的分离效果。

应用方法 :

压铸:gleitmo 705适用于薄且均匀的薄膜,用刷子或流苏。 刻录在上述的熔点或火焰熄灭直到糊状涂层干燥 - 直到浅灰色干得到残余物。

特点

温度范围:-20 / +1000°C

,exellently适合作为铸杓面临

润滑和分离良好,即使在非常高的温度下

增加了功能的可靠性和延长使用寿命的热的系统和工具

gleitmo 705 is a grey lubricating paste, with good spreading properties, for use at high temperatures. A special synthetic oil containing a large amount of a gleitmo solid lubricant combination provides this product with good lubrication and separating properties. The carrier oil evaporates gradually at continuous temperatures exceeding 180 °C. A dry lubricating film is formed which lubricates under mixed and boundary friction conditions up to +1,000 °C and provides protection against wear. There is only very slight residue from the carrier oil, and this residue has a favourable effect in the subsequent lubrication process.

Lubrication of low-speed bearings, bolts, hinges, slipper pads and slide rails on firing, drying and an-nealing systems. Casting channels in permanent mold casting plants. Die casting machines: ejector pins and other moving parts.

Wherever high temperatures preclude the use of oils and greases and wherever slow, also oscillating movements occur or a good release effect is re-quired.

Furthermore gleitmo 705 is suitable as facing for casting ladles, tools, funnels and spouts in aluminium die casting.

In die casting: Apply a thin and uniform film of gleitmo 705 using a brush or tassel. Burn in above the melting or flame off until the pasty coating is dry - until the dry light-grey residue is obtained.

temperature range: -20 / +1000 °C

is exellently suited as casting ladle facing

lubricates and separates well even at very high temperatures

increases functional reliability and prolongs the service life of hot systems and tools